Our carbide end mills are products that can achieve

long tool life to cover various materials

by our original coating technology.

Molding technologies are used to seal semiconductors by electrically insulating them from the outside using resin. These technologies are essential to ensure the reliability of semiconductors.

At TOWA, we develop dicers and handlers, the main functions of singulation equipment.

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied a number of ultra-precision molds to the market. These products have been highly acclaimed by customers.

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.

Supporting TSS with IoT technologies TEN-System

TEN-System supports TSS comprehensively with IoT and a web system, allowing us to provide appropriate services promptly.

In addition to trading in the global market, we consistently engage in purchase, reclamation, sales, and provision of support, all essential for trading used equipment.

Our carbide end mills are products that can achieve

long tool life to cover various materials

by our original coating technology.

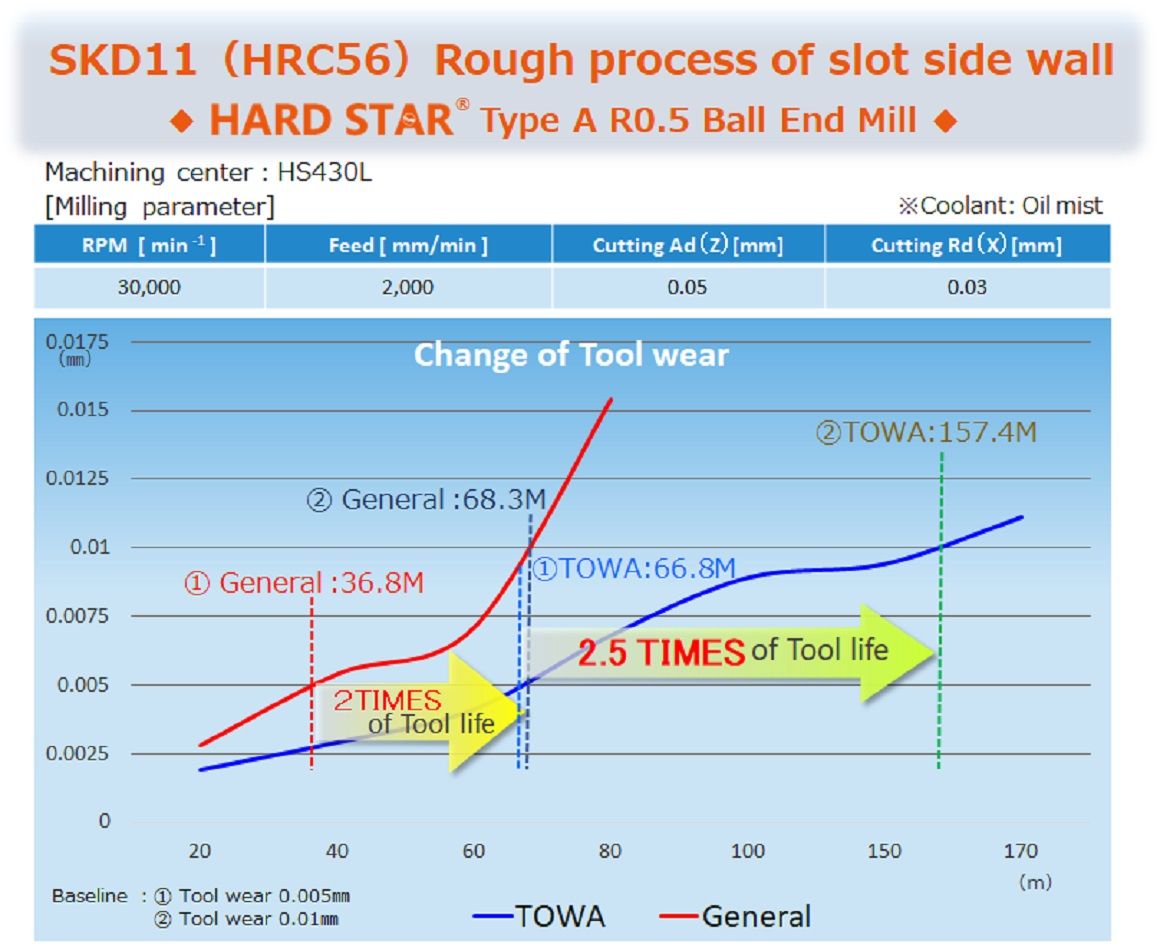

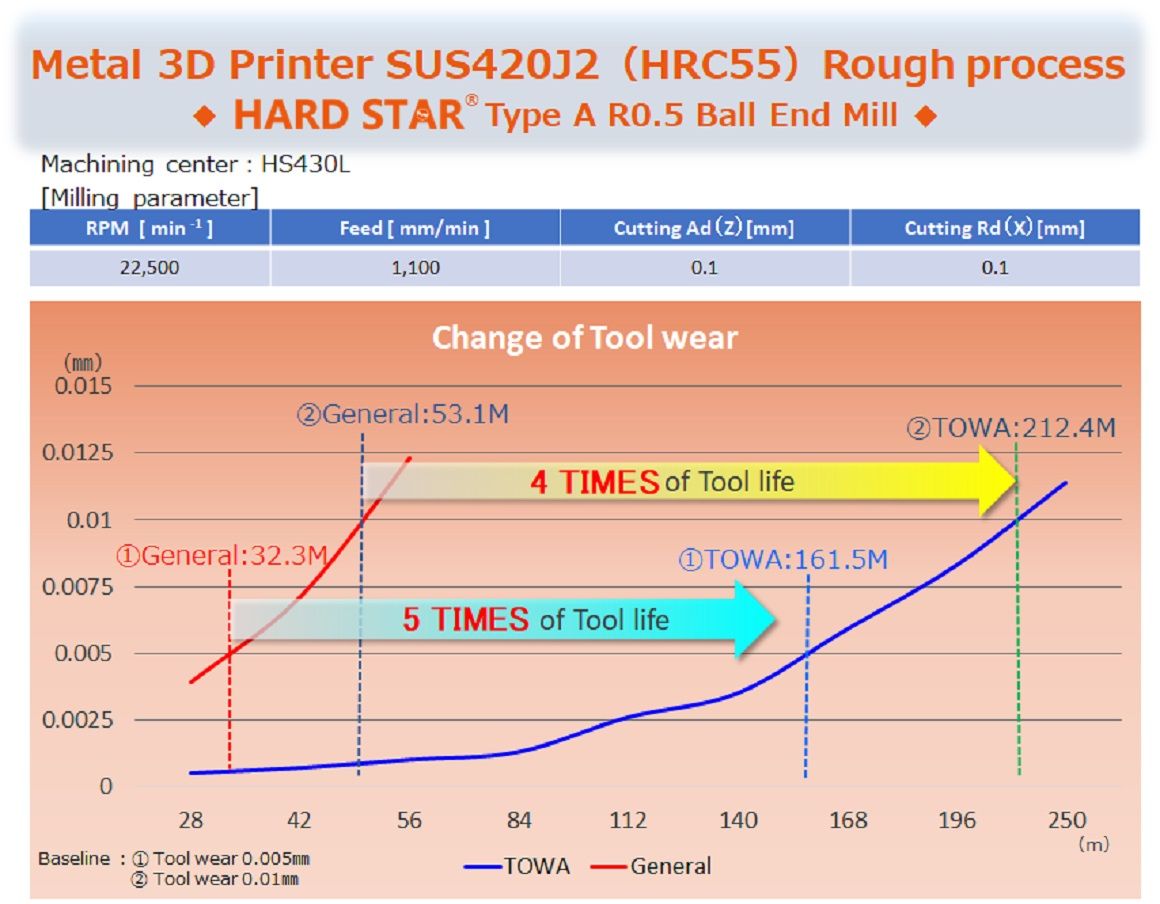

TOWA unique film-forming technology based on sputter deposition can achieve extra-long life for high-hardness(HRC50 or more) materials milling.

Achieves outstanding cutting performance and long tool life in dry environments.

It also demonstrates high performance in metal 3D processing.

Our Commitment to Technologies

From

Kyoto to

the World

From

Kyoto to

the World

5 Kamichoshi-cho, Kamitoba, Minami-ku, Kyoto-shi, Kyoto

601-8105 JAPAN

TEL (+81)75-692-0250(main)

FAX (+81)75-692-0270

Certified to ISO 9001:

the international standard for quality

assurance.

(Excluding Bandoh Memorial Research Laboratory

and INNOMS Promotion

Dept.)

©1999-2024 TOWA JAPAN ALL Rights Reserved.