Molding technologies are used to seal semiconductors by electrically insulating them from the outside using resin. These technologies are essential to ensure the reliability of semiconductors.

Products

Molding Equipment

At TOWA, we market molding equipment (resin sealing equipment) that utilizes the transfer method. With this method, a flowable resin for protecting the semiconductor chips is applied to the area around the semiconductor chip via a gate (supply port) before it is cured. In addition, we have also developed and market molding equipment that utilizes the compression method, whereby semiconductor chips are immersed in a flowable resin in advance and then the flowable resin is cured. Semiconductor manufacturers use larger lead frames and substrates in an attempt to improve productivity and reduce the production cost. In addition, semiconductor molding technologies are required to be compatible with the slimmer dimensions and higher integration of semiconductor devices and with increased thickness for compatibility with power devices and modularization. Our molding equipment caters to these various needs.

Products

| Compression Molding Equipment | Transfer Molding Equipment | Singulation Equipment | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PMC |

LCM |

YPM |

EZS |

Y1R |

Y1E |

FMS |

||||||||

| CPM1080 | CPM1180 |

PMC2030-D |

YPM1200 | YPM1180 | YPM1120 | YPM1080-SP | YPM1080-EP | EZS1120 | Y1R1060 | Y1E4120 | ||||

|

MAP-BGA |

- | - | ● | - | - | ● | ● | ● | ● | ● | ● | ● | ● | ● |

|

PBGA |

- | - | - | - | - | ● | ● | ● | - | - | ● | ● | ● | - |

|

MAP-QFN |

- | - | ● | - | - | ● | ● | ● | - | - | ● | ● | ● | ● |

|

Individual piece QFP |

- | - | - | - | - | ● | ● | ● | - | - | ● | ● | ● | - |

|

QFP/SOP/DIP |

- | - | - | - | - | ● | ● | ● | - | - | ● | ● | ● | - |

|

Wafers(WLP) |

● |

● |

- | ● | - | - | - | - | - | - | - | - | - | - |

|

Panels(PLP) |

● |

● |

● | - | - | - | - | - | - | - | - | - | - | - |

|

Power device semiconductor |

- | - | - | - | - | ● | ● | ● | - | - | ● | ● | ● | - |

|

Sensors/Module Products |

- | - | ● | - | - | ● | ● | ● | - | ● | - | - | - | - |

|

LED |

- | - | - | ● | ● | ● | ● | ● | - | - | - | - | - | - |

CPM-Series

CPM1080

CPM1180

The CPM-series molding equipment is capable of molding wafers and panels, which are increasing in size, by utilizing the compression method.

The molding of large wafers and panels is enabled by our high-precision compression technologies. The CPM1080, which is capable of wafer level package (WLP) molding of up to 12-inch wafers (Φ300mm) and panel level package (PLP) molding up to 320mm X 320mm, permits the use of liquid resins as well as granular resins that are available at lower cost. In addition, the CPM1180, capable of molding ultra-large panels, enables high productivity and significant cost reduction. The CPM1180 can mold 18-inch wafers (Φ450mm) and 660mm X 620mm panels.

PMC-Series

PMC2030

The PMC series is a molding system to realize high quality molding by compression method.

Applicable workpiece size is up to 100 mm x 300 mm, and TOWA original ultra-high precision press achieves high package accuracy.

We also contribute to further productivity by strengthening measures against contamination in the equipment.

Besides, molding equipment for heat sink/metal shield is applicable for both exposure molding of heat sink/metal shield and conventional package molding with simple switching.

LCM-Series

LCM1010

LEDs are widely utilized in a variety of equipments, such as for the backlights of LCD panels, projectors, illumination lamps, and sensors.

The LCM-series molding equipment is capable of sealing liquid resins of LEDs and other devices.

The compression method enables the high-volume production of LED packages with the effective utilization ratio of resin of 100%.

This method also permits simultaneous LED chip molding and resin sealing, ensuring even, stable lens shape and high-precision molded products.

FFT-Series

FFT1030

The FFT-series is the ideal equipment for high-mix variable-volume production and prototype evaluation.

The compression method is virtually free of resin flow and holds down the pressure on chips. It therefore ensures the stable molding of semiconductors with thin chips, narrow pitch, long wires, and low-k materials with low permittivity.

It is a compression molding equipment compatible with granular resin and liquid resin (silicone, epoxy).

YPM1180

YPM1080-SP

The YPM-series molding equipment utilizes our world-leading transfer method.

The YPM1180 has a clamping force of 180tons while occupying the same space as the 60-ton equipment. This is achieved through the use of a small, high-precision press with a hold frame structure that we have developed ourselves.

In addition, the ideal mold surface pressure has been enabled by achieving even clamp surface pressure, which makes the product compatible with large lead frames up to 100mm X 300mm in size.

It permits conversion between side-gate molding and top-gate molding by replacing the mold and kit. (Top-gate molding is optional.)

For the YPM1080-SP, the structure of the mold has been simplified, which has resulted in improved maintainability and enabled significant cost reduction.

Further, by utilizing our proprietary technologies, its structure is compatible with mold underfill (MUF) molding as well. The YPM-series products thus enable both lower production cost and higher molding quality.

Y1R / Y1E-Series

Y1R1060

Y1E4120

Y1R / Y1E-series are our longtime seller transfer type molding equipment.

The Y-series equipment, which we began developing in 1992, is the world's first equipment that permits the press modules to be detached in accordance with the production quantity. The concept of the Y-series was highly acclaimed by customers and it became a best-selling series, unprecedented among molding equipment around the world.

In order to further improve performance, we have achieved substantial reductions in manufacturing costs by improving parts, changing parts, equipment assembling, reviewing control systems, and so on. We have a lineup of equipment (Y1R1060, Y1E4120) that can meet the customer's product needs. With many years of proven product performance, the Y1R / Y1E-series contribute to customer's production with high reliability and productivity.

EZS-Series

EZS1120

The EZS series is a transfer molding system and ideal for wide-variety and small-amount production.

Improves the interchangeability by simplifying the exchange of KIT and cavities, and contributes to high production efficiency.

In addition, the compact footprint makes it easy to install and move in the factory.

Mold Release Films

T-Series

Mold release films are used to enable molded products, such as semiconductors and LED lenses, to be easily removed from molds. They are required to be highly heat-resistant and not to significantly affect the physical properties of molded products, in addition to having superior release properties.

Mold release films are consumables, so their prices should ideally be as low as possible.

The T-series mold release films are optimized for molding equipment and satisfy all these requirements concerning release properties, heat resistance, impact on products, and cost.

The use of the T-series contributes significantly to reducing the total annual cost.

Product Case

-

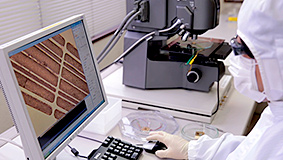

Introduce our manfufacturing technology used for finger print sensors.

-

Introduce ultra precision element technologies that support the manufacturing of high quality and high precision optical parts used in head up displays.

-

Introduces our molding technologies andequipment, which improves the reliability of ECUs and various automotive electronic devices.

-

Introducing the floating image lens and various application examples based on our ultra-precision mold processing technology, EF technology, and injection molding technology.

From Kyoto to the World

From Kyoto to the World