We provide high-precision, high-quality transfer molds and compression molds by utilizing our advanced design technologies and analysis technologies.

Our Commitment to Technologies

Mold Design Technologies

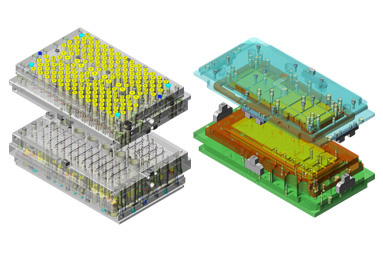

We design molds using a system where the processes from the creation of product drawings, layout, and the arrangement of parts to the creation of data for processing are automated based on 3D CAD data. To ensure optimal designs, we also examine the molds before producing them through CAE analysis using 3D data.

Utilizing 3D CAD Data for the Automatic Design of Molds

Based on product drawings and specifications from customers’ requests, we convert them into 3D data and integrate them with our database enabling efficient mold designing. Design quality improvement and speed up of the design process can be achieved by automating several tasks such as searching and configuring design data.

Example of mold design automation

- 1.User specification input

Enter required specifications such as mold size and product size in the database

- 2.Create molded product model

Automatically create 3D model of product based on input information

- 3.Layout design of molded product

Automatically create 3D layout model of cull, gate, airvent etc.

- 4.Design of mold chase assembly model

Automatically create 3D assembly model of mold chase based on required specification

- 5.Design of molded product

Based on the 3D model of the final product, automatically create a 3D model of the mold chase.

- 6.Layout of mold chase parts

Automatic layout of the mold chase parts based on the molded product information

(Manual layout if there are any special parts).

- 7.Create parts list

Automatically create parts list based on the 3D model.

- 8.Create processing data for manufacturing

Automatically create proceessing data such as process informaton and CAM data.

- 9.Output

Automatic output of parts model, parts list, processing data.

- 1.User specification input

Enter required specifications such as mold size and product size in the database

- 2.Create molded product model

Automatically create 3D model of product based on input information

- 3.Layout design of molded product

Automatically create 3D layout model of cull, gate, airvent etc.

- 4.Design of mold chase assembly model

Automatically create 3D assembly model of mold chase based on required specification

- 5.Design of molded product

Based on the 3D model of the final product, automatically create a 3D model of the mold chase.

- 6.Layout of mold chase parts

Automatic layout of the mold chase parts based on the molded product information (Manual layout if there are any special parts).

- 7.Create parts list

Automatically create parts list based on the 3D model.

- 8.Create processing data for manufacturing

Automatically create proceessing data such as process informaton and CAM data.

- 9.Output

Automatic output of parts model, parts list, processing data.

Optimizing Design Contents through CAE Analysis

The role design plays in mold manufacturing is important. Especially, since resin flow behavior is a big problem related to the customer’s production cost, it is necessary to reveal the issues affecting quality and productivity in the early stages of mold design and development and reflect it in the design.

We have been conducting analytical research on resin flow behavior from both numerical calculations and actual results. From years of research and development, we have established a technology for the 3D analysis of resin flow in molds based on CAE, and we make use of this technology for mold design.

Problems with resin flow in molds can cause external defects such as voids, wire sweep leading to short circuit, or internal air bubbles resulting in cracks, for example, which reduce the product yield. We make use of CAE analysis techniques for reducing the risk of defects, and design molds taking into account the most suitable conditions for customer’s products and optimal quality and productivity.

Product List

-

TOWA is a leading company in the semiconductor molding equipment market. We offer equipment using our proven transfer molding method, and high quality / flow free compression molding method.

-

With our expertise in the field of singulation, high speed handling and image analysis technology, we offer high quality singulation equipment.

-

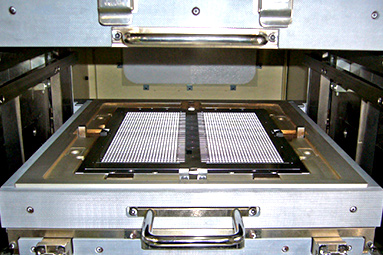

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied a number of ultra-precision molds to the market. These products have been highly acclaimed by customers.

-

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.

From

Kyoto to

the World

From

Kyoto to

the World