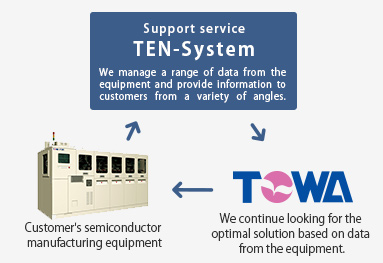

TEN-System supports TSS(Total Solution Service)

comprehensively with IoT and a web system,

allowing us to provide appropriate services promptly.

TEN-System supports TSS(Total Solution Service)

comprehensively with IoT and a web system,

allowing us to provide appropriate services promptly.

We are planning to start adding functions in April 2017, one by one.

If semiconductor manufacturing equipment is shut down during its operation due to a failure, it may affect the customer production plan.

At Towa, we provide Total Solution Service (TSS) with TEN-System, a new service that utilizes the Internet of things (IoT) and machine-to-machine (M2M) technologies for customer support and service.

This page explains the TEN-System, which supports "TSS with TEN-System". TEN-System consists primarily of the following three aspects:

For online support, we have introduced an equipment chart and a wearable device.

The equipment chart displays a list of the current conditions of registered semiconductor equipment and errors that have occurred with it. It also shows the operational statuses and errors in a specified period, enabling the cause of a failure or an accident to be identified promptly and accurately.

Further, the use of a wearable device, which is worn by the customer, enables our engineer to provide support to the person from a distant location. This online support enables a faster response than before and permits customers to reduce the man-hours and costs incurred due to a failure or an accident.

In the parts supply service, we quickly supply customers with the parts they need by constantly checking the inventory statuses of parts at our partner dealers all over the world through a web system.

For predictive maintenance, we install devices such as vibration meters in the semiconductor manufacturing equipment and collect data on the equipment's conditions. These data are analyzed using the expertise of Towa, which has an extensive track record as a manufacturer of semiconductor manufacturing equipment. Based on the results of the analysis, the equipment itself discovers signs of failure and notifies the customer and Towa of the signs by e-mail while also activating the alarm. This enables the cause of the failure to be determined before the equipment stops operating abnormally due to the failure.