Based on our extensive experience with injection molds, we enable mass-production molding with a consistent line and cleanroom environment by making effective use of our ultra-high precision microfabrication technologies.

Our Commitment to Technologies

Fine Plastics

Plastics are essential materials in many industrial fields. Above all, engineering plastics with superior properties are used in telecommunications, information appliances, healthcare, optics, and other fields. Since our founding, we have maintained a consistent approach to the design, production, molding, and assembly of injection molds for engineering plastics. As a result, we provide high-quality molded products that are highly valued in the market.

High quality mass production molding utilizing ultra precision and fine processing technology

Since the company’s founding, using our core ultra precision mold technology, we have been designing and manufacturing injection molding dies for fine plastic, also called engineering plastics. Not only do we mold, but also assemble plastic products. In addition to stably supplying high quality fine plastic molded parts, we have established a flexible supply system that can be applied to both mass and small lot production.

We are aware of our customers’ needs with the spirit of “quarter lead.” The high precision and high quality plastic molded products produced by our solutions and FA production lines have been widely recognized a wide range of fields.

Our products have been highly praised in medical equipment, camera helicoids, auto fuses, light fiber connectors, automotive connectors and micro lens arrays.

For example, we helped to investigate and take counter measures against why the tip of core pin in a medical syringe tends to break, for a particular customer. We enhanced the productivity of the product through this investigation.

In camera lens barrels, due to the complexity of its shape and structure, high accuracy is expected in processing and assembly. We contributed to make the product widely accepted in the market by providing a final product that meet’s the customer’s needs. In order to improve the overall accuracy, we verified the product from several angles such as, molding parameters, molding compound, product dimensions, fitting accuracy, and sliding conditions.

Injection molding machine

Molding of fine plastics for medical use

Contributing to the future society with high accuracy, high quality, and high reliability

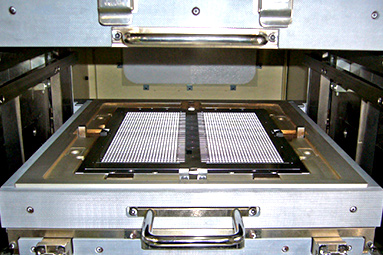

The strength of our fine plastic molded products is high-precision mass production molding, using EF mold tools transferred with ultra precision microfabrication. Another strength is our stable and high quality molding in a clean room environment.

Aiming a process capability index of more than 1.5, and under a clean room environment of over Class 1000, not only do we realize the accuracy and quality requested by our customers, but we can mold stabily with efficient cycles.

Our final products, produced from high-grade molds in a clean room environment, boasts the precision and cosmetic quality that our customers anticipate. Medical equipment parts/ asssembled parts, bio measurement / inspection devices for advanced medical care, optical equipment parts, lenses, etc…We aim to change the medical system in the future with next-generation fine plastic.

We will also contribute to realize a prosperous future in the sensor field to support IoT (the technology that connects things to the Internet).

Cleanroom

Product List

-

TOWA is a leading company in the semiconductor molding equipment market. We offer equipment using our proven transfer molding method, and high quality / flow free compression molding method.

-

With our expertise in the field of singulation, high speed handling and image analysis technology, we offer high quality singulation equipment.

-

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied a number of ultra-precision molds to the market. These products have been highly acclaimed by customers.

-

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.

From

Kyoto to

the World

From

Kyoto to

the World