Singulating Products by Cutting Them with High Precision

and at High Speed

Singulating Products by Cutting Them with High Precision

and at High Speed

Singulation, one of core technologies in the post-process of semiconductor manufacturing, is a technology we are working on since the 1990s. We combine high-speed handling technology and image analysis technology with cutting technology that we have cultivated over many years, and we are offering high-quality singulation equipments.

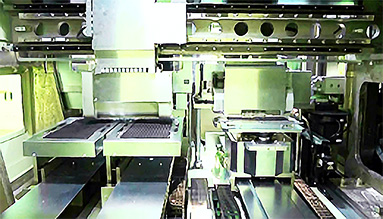

In singulation process, the molded substrate is divided into individual pieces by a dicer in a molding machine. Separated products are transported by a handler and stored in a tray or the like.

The world’s first singulation equipment was developed by the group company of TOWA. Since then, we have been offering a system dedicated to package singulation, by developing our own Dicer and Handler.

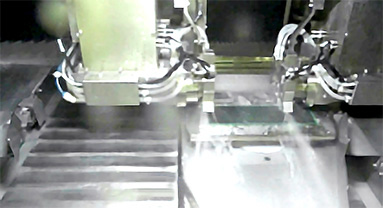

For dicers responsible for individualizing products, it is important to deal with shrinkage of resin during molding and temperature change during cutting.

Corresponding to the warp of the board, by dividing into pieces with high precision, the yield of products is greatly improved. We are constantly developing and improving our company so that we can develop Dicer by ourselves and provide optimal singulation method according to customer’s type of products to be manufactured.

The handler which is another major constituent function contributes to the improvement of the customer’s production capacity by high throughput by taking advantage of know-how accumulated over many years by our company.

In recent years, in addition to reducing production costs, there is a strong demand for compactness and thinning of products. For small products up to 1mm X 1mm, TOWA adopts an adsorption jig type using a vacuum pump rather than a tape type which isn’t suitable to reduce the manufacturing cost.

In the future, as substrate size increases further, high precision is required for rotation control of Dicer’s cut table. We will respond to such issues quickly and flexibly with our own Dicer.

The first-generation singulation system

Alignment (The optimal cutting position along the workpiece is determined.)

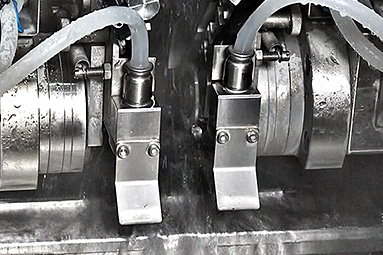

Dicer (The substrate on the cutting table is cut with the blade.)

Handler (For handling and storing products in the tray.)

TOWA is a leading company in the semiconductor molding equipment market. We offer equipment using our proven transfer molding method, and high quality / flow free compression molding method.

With our expertise in the field of singulation, high speed handling and image analysis technology, we offer high quality singulation equipment.

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied a number of ultra-precision molds to the market. These products have been highly acclaimed by customers.

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.