Ultra-precision microfabrication technologies for creating compact,

high-performance products

Ultra-precision microfabrication technologies for creating compact,

high-performance products

In order to make products smaller with higher performance, ultra precision micofabrication technology to minaturize constituent parts with high precision is necessary. At TOWA, we undertake research and development from a wide range of perspectives related to ultra-precision micro-fabrication, including the environment, devices, equipment, measurement, evaluation, tools, materials, and processing methods, it is compatible with various processing materials such as metal, resin and ceramics.

In order to achieve both compact and high performance products, high precision and miniaturization of components and molds are required. As a leading company of ultra-precision molds, with our ultra-precision processing technologies, we can respond to a wide range of customers’ needs, and enable high precision and high quality micro-fabrication.

Based on the know-how that we have accumulated as core technology, we have developed our unique automated equipment (with artificial intelligence) in collaboration with a machine tool manufacturer. We have thus enabled fully unattended processing. With State-of-the-art equipment and skilled technologies enabling the processing of high-hardness materials in the submicron order, we provide comprehensive solutions for a range of precision processing needs, including semiconductor plastic encapsulation molds and LED molds.

Curved surface composite processing

Where three different types of processing – that is, cutting, grinding, and electric discharge – are applied regularly to the cavity of an R-shaped curved surface to create detailed patterns, even if a variety of processing is applied to the curved surface, we can achieve high level of precision machining of 1 μm or less in the level difference between the worked surfaces.

Combined machining of an R-shaped surface

R-shaped cross-section surface machining accuracy

Pocket shape surface mirror finish

The use of our CBN endmill for cutting enables a surface quality of 5 nm (Ra) to be achieved, making hand polishing unnecessary. Besides mirror surface, surface finish of high grade and added value is also possible for high hardness materials such as hairline shape and lattice shape ones.

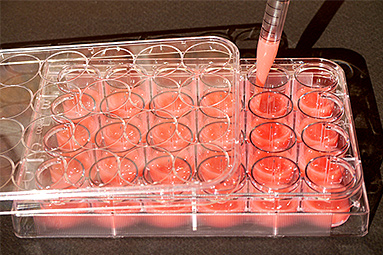

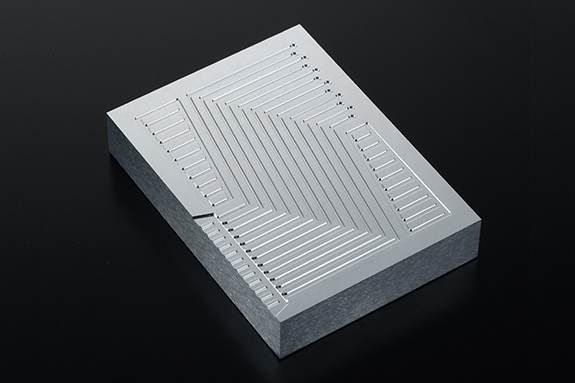

Mold for fuel cell separator

With our high technical capabilities, our company can respond to high difficulty level processing requests such as molds for fuel cell separator which requires miniaturization and higher precision technologies.

Mirror-like finish of pocket-shaped surface

Mold for fuel cell separator

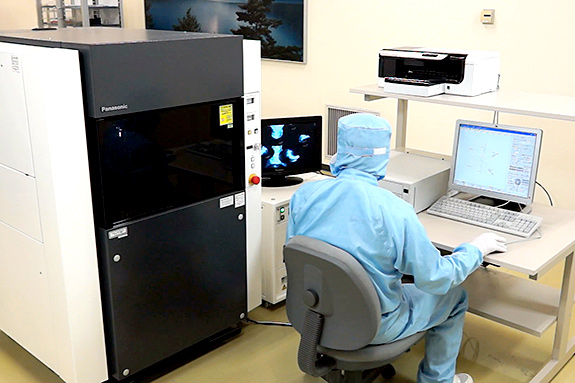

In order to realize processing in nanometer order, we are working on microfabrication using our own equipment in a work environment equivalent to that of a clean room.

Supporting our nano-level processing as well as environment and equipment are elemental technologies such as measurement, evaluation, tools and materials, and super precision microfabrication technology and processing methods that we have cultivated over many years.

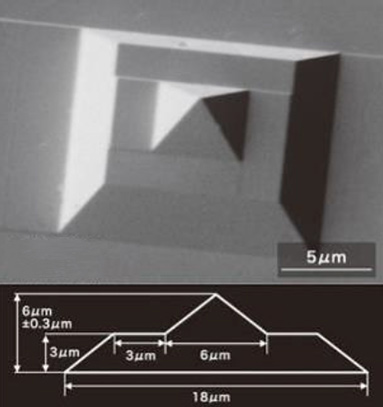

Our microfabrication technology boasts processing precision that allows 50,000 pyramids of height 6μm in the range of φ 220 mm to be arranged with an accuracy of 0.3 μm.

Moreover, based on abundant experience, we propose by combining optimal processing method consisting of our proprietary nano processing technology such as ultrasonic elliptical vibration processing, high speed micro milling, multi-axis synchronous control , and MEMS process, With nano order surface quality and shape accuracy of submicron order, we can meet the precision processing demands from our customers.

We also manufacture molds for products that require nano order processing, such as microlens arrays of head up display.

Equipment and environment for microfabrication

TOWA is a leading company in the semiconductor molding equipment market. We offer equipment using our proven transfer molding method, and high quality / flow free compression molding method.

With our expertise in the field of singulation, high speed handling and image analysis technology, we offer high quality singulation equipment.

As the leading company in resin sealing technologies for semiconductors and other electronic components, we at TOWA Corporation have supplied a number of ultra-precision molds to the market. These products have been highly acclaimed by customers.

Developed by utilizing technologies cultivated through the manufacture of ultra-precision molds, End mills and Drills from TOWA boast high precision, superior abrasion resistance, and a long life-span.